Durability and Longevity: Understanding the Benefits of Chemical Fuel Hoses

Introduction:

Chemical fuel hoses play a crucial role in various industries where the safe and efficient transfer of liquids is essential. These hoses are specifically designed to withstand the challenges posed by chemicals, fuels, and other potentially corrosive substances. With their exceptional durability and longevity, chemical fuel hoses offer a range of benefits that make them an excellent choice for industrial applications.

Durability:

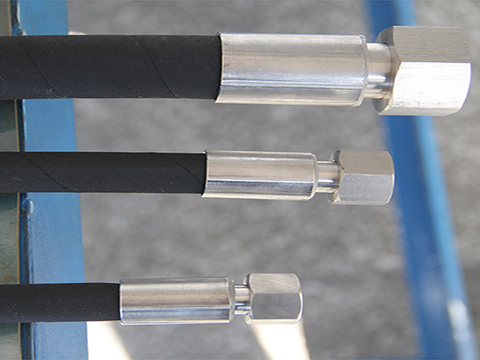

One of the primary advantages of chemical fuel hoses is their remarkable durability. These hoses are constructed using high-quality materials that can withstand the harshest environments and resist the corrosive effects of chemicals. Whether it's transferring gasoline, diesel, hydraulic fluids, or other aggressive substances, chemical fuel hoses are engineered to maintain their structural integrity over extended periods. Their synthetic rubber or thermoplastic inner linings provide excellent resistance to chemical reactions, while their reinforced exteriors ensure maximum strength and flexibility.

Longevity:

Chemical fuel hoses are built to last. With proper maintenance and care, these hoses can endure the rigors of continuous use, resulting in longer service life and reduced replacement costs. Their robust construction minimizes the risk of leaks, cracks, or ruptures, ensuring uninterrupted fluid transfer operations. Additionally, chemical fuel hoses are designed to withstand extreme temperature variations, making them suitable for use in both hot and cold environments. This adaptability further enhances their longevity, making them a reliable option for various industries.

Safety:

Chemical fuel hoses prioritize safety in fluid transfer operations. They are engineered to minimize the risk of leaks, which can lead to accidents, environmental damage, and financial losses. Chemical fuel hoses undergo rigorous testing to ensure compliance with industry standards and regulations, guaranteeing their ability to handle the specific chemicals or fuels they are designed for. By choosing chemical fuel hoses that meet or exceed these standards, industries can safeguard their employees, equipment, and the environment.

Applications:

Chemical fuel hoses find applications in a wide range of industries, including manufacturing, construction, agriculture, and transportation. They are commonly used in fueling stations, chemical plants, oil refineries, and even in marine and aviation sectors. Chemical fuel hoses enable the safe and efficient transfer of various liquids, such as gasoline, diesel, jet fuel, oils, solvents, and acids, making them indispensable in these industries' day-to-day operations.

Conclusion:

Chemical fuel hoses offer exceptional durability and longevity, making them a reliable choice for industrial fluid transfer needs. With their ability to withstand harsh environments, resist chemical reactions, and ensure safety, these hoses contribute significantly to the smooth and efficient functioning of various industries. By investing in high-quality chemical fuel hoses, businesses can optimize their operations, reduce downtime, and prioritize the safety of their employees and the environment.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *