Enhancing Safety and Performance: The Importance of Steel Wire Reinforcement in Hydraulic Hoses

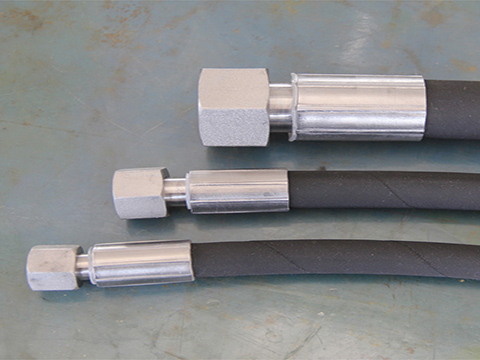

Hydraulic hoses are critical components in various industries, responsible for transmitting fluid power from one component to another. These hoses operate under high pressure and are subjected to demanding conditions. To ensure their reliability, safety, and longevity, steel wire reinforcement is an essential feature in hydraulic hose construction. In this article, we will explore the significance of steel wire reinforcement and its role in enhancing the performance of hydraulic hoses.

The Role of Steel Wire Reinforcement:

Steel wire reinforcement provides crucial structural integrity to hydraulic hoses, enabling them to withstand high pressure and resist deformation. By adding strength and stability, steel wire reinforcement ensures that hydraulic hoses can withstand the immense forces and pressures exerted during operation. Furthermore, it helps prevent the hose from collapsing or bursting, ensuring the safety of personnel and equipment.

Benefits of Steel Wire Reinforcement:

High Pressure Resistance: Steel wire reinforcement allows hydraulic hoses to handle extreme pressure without failure. The tensile strength of steel wire enables hoses to maintain their shape and structure even under tremendous pressure, avoiding leakage and potential hazards.

Flexibility and Bendability: While steel wire reinforcement provides strength, it does not compromise the flexibility and bendability of hydraulic hoses. The wire reinforcement is carefully designed and positioned to allow the hoses to flex and bend without losing their structural integrity, ensuring efficient fluid transmission in tight spaces.

Abrasion and Impact Resistance: Hydraulic hoses are often exposed to harsh environments, including abrasion and impact. The steel wire reinforcement provides a protective layer, shielding the hose from external damage and preserving its performance over time.

Different Types of Steel Wire Reinforcement:

Steel wire reinforcement comes in various configurations, including single wire braids, double wire braids, and spiral wire reinforcement. The choice of reinforcement depends on the application's specific requirements, such as pressure rating, flexibility, and temperature resistance. Each configuration offers unique benefits, allowing hydraulic hoses to cater to a wide range of industrial needs.

Conclusion:

The importance of steel wire reinforcement in hydraulic hoses cannot be overstated. Its inclusion ensures the hoses can withstand high pressures, resist deformation, and maintain their structural integrity. With steel wire reinforcement, hydraulic hoses provide reliable and safe fluid power transmission, minimizing the risk of accidents and equipment failure. Manufacturers, engineers, and end-users must recognize the significance of steel wire reinforcement and ensure its presence in hydraulic hose assemblies. By prioritizing the use of high-quality hoses with proper steel wire reinforcement, industries can enhance safety, improve performance, and achieve optimal productivity in their hydraulic systems.

Different Types of Steel Wire Reinforcement:

Steel wire reinforcement comes in various configurations, including single wire braids, double wire braids, and spiral wire reinforcement. The choice of reinforcement depends on the application's specific requirements, such as pressure rating, flexibility, and temperature resistance. Each configuration offers unique benefits, allowing hydraulic hoses to cater to a wide range of industrial needs.

Conclusion:

The importance of steel wire reinforcement in hydraulic hoses cannot be overstated. Its inclusion ensures the hoses can withstand high pressures, resist deformation, and maintain their structural integrity. With steel wire reinforcement, hydraulic hoses provide reliable and safe fluid power transmission, minimizing the risk of accidents and equipment failure. Manufacturers, engineers, and end-users must recognize the significance of steel wire reinforcement and ensure its presence in hydraulic hose assemblies. By prioritizing the use of high-quality hoses with proper steel wire reinforcement, industries can enhance safety, improve performance, and achieve optimal productivity in their hydraulic systems.

Leave Your Product Requirements

Your email address will not be published. Required fields are marked *